NZ Farming Contractors: Is your operation fully optimised for effective performance and cost reduction?

FarmChief has the perfect solution for those needing to significantly reduce high input costs, spend less on labour, and increase overall efficiency. Choose the FarmChief complete rotary strip-tillage system to see instant savings in the field and in the wallet.

It only takes a quick glance at the top headlines on the news to understand that costs for pretty much everything is rapidly rising. After a sustained period of low OCR, households are now thinking about how to reduce expenses, or remove them altogether, just so they can get by.

Of course, this extends to the agriculture industry as well, and as a community-focused organisation, we at FarmChief are constantly looking for ways to help contractors reduce some costs.

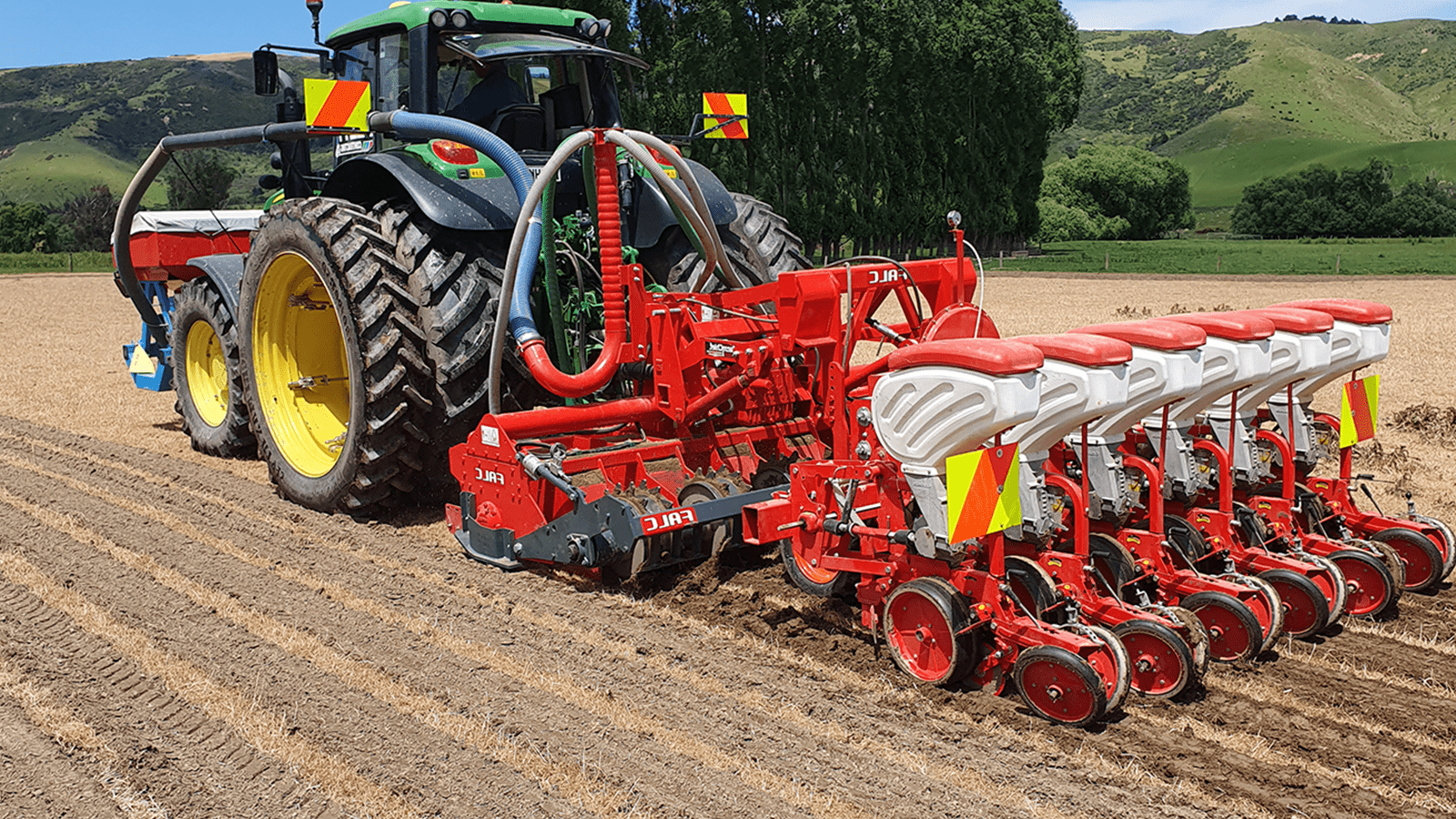

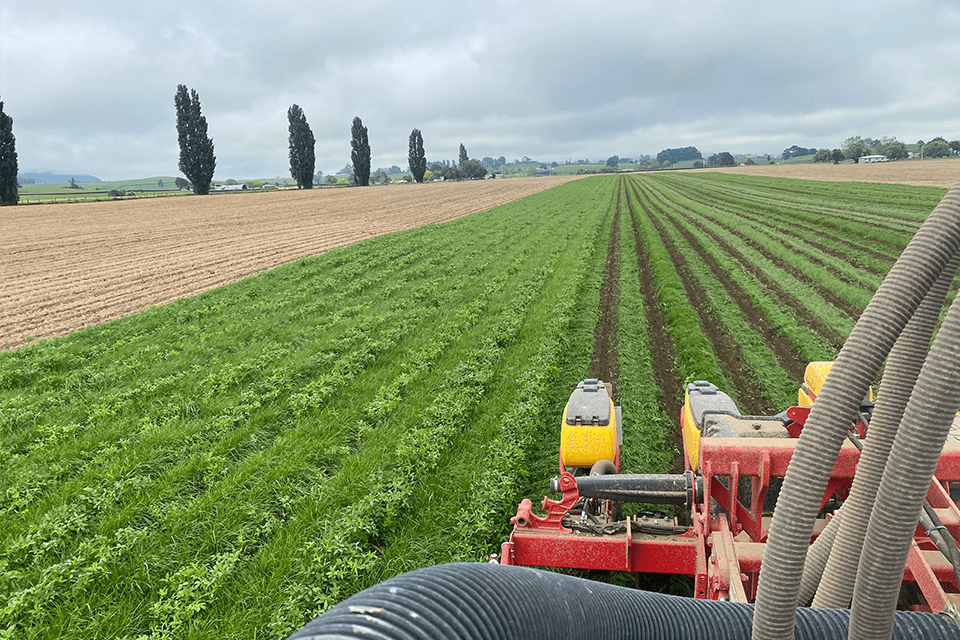

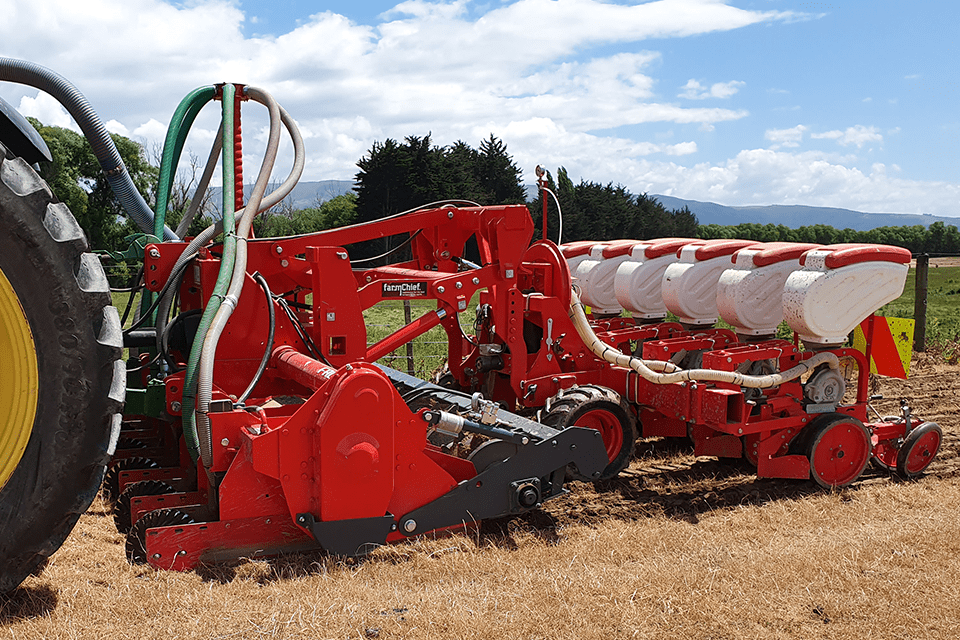

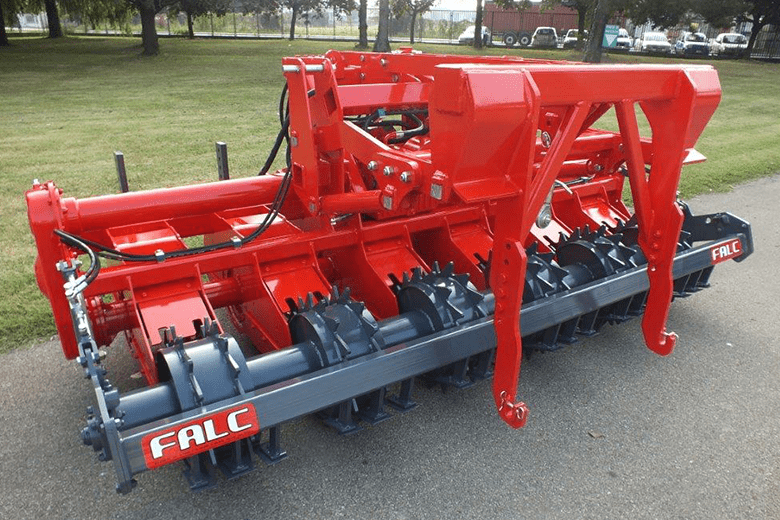

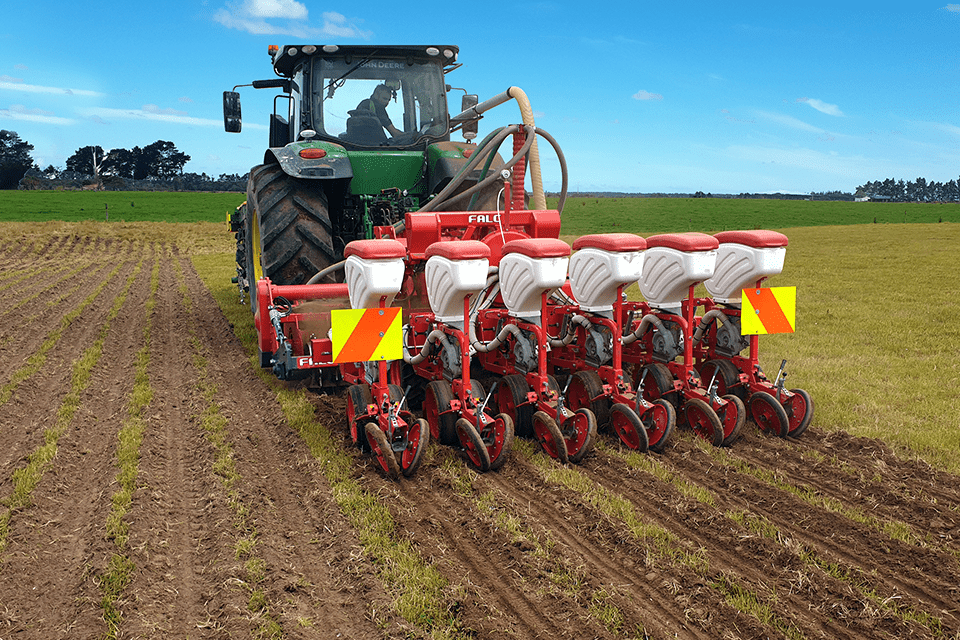

The FarmChief complete rotary strip-tillage system is designed to reduce what used to be up to four passes in the paddock down to one, whilst achieving greater results when compared to traditional cultivation techniques.

|

Save BIG On Fuel – Traditional methods of sowing and seedbed preparation for winter feed crops like fodder beet and swedes or maize crops could take up to four passes on the paddock; Primary and secondary cultivation with a plough and power harrow, followed by a roller, and finally drilling the seed, all require significant time in the tractor towing heavy machines, burning plenty of diesel. The way fuel prices are going, it’s only going to become more expensive to operate. Consider the FarmChief complete rotary Strip-Till system to optimise your input costs, improve efficiency and reduce time spent in the field. By combining the Rotary Strip-Till, Front Fert Tank and Precision Planter, we’re seeing many customers cultivate, fertilise and plant, all in one pass, making for huge savings at the pump. |

|

|

|

Reduce Labour and Wage Headaches – Too much work and not enough employees to do it all? That’s a common problem being felt throughout New Zealand, right now. Solve it by reducing your labour costs. The FarmChief Rotary Strip-Till System requires only one operator and take less time than traditional cultivation work, meaning you can get your team to the next job, quicker. Additionally, reducing the number of operators on each job makes for a lighter wage bill at the end of the month, all while maintaining the number of jobs you are able to get to. |

Machine prices are going up, along with the rest of your costs. Make the smart decision to invest in your productivity and see the savings as soon as you hit the field.

Keen to get started? Check out the range here:

|

|

|

|

Contact Us For More Information | Read More On Strip Tillage