Keeping your effluent ponds up to scratch can be dirty, time-consuming work. Here are our top reasons for keeping on top of it.

Dairy farmers, with the costs of pretty much everything going through the barn roof, have you considered spreading your on-farm effluent on pasture? Not only does this take away some of the costs of synthetic fertiliser, but it also reduces the costs of frequently emptying your slurry pond or tank. It’s also great for the environment and helps keep the council (and your neighbour onside) as well.

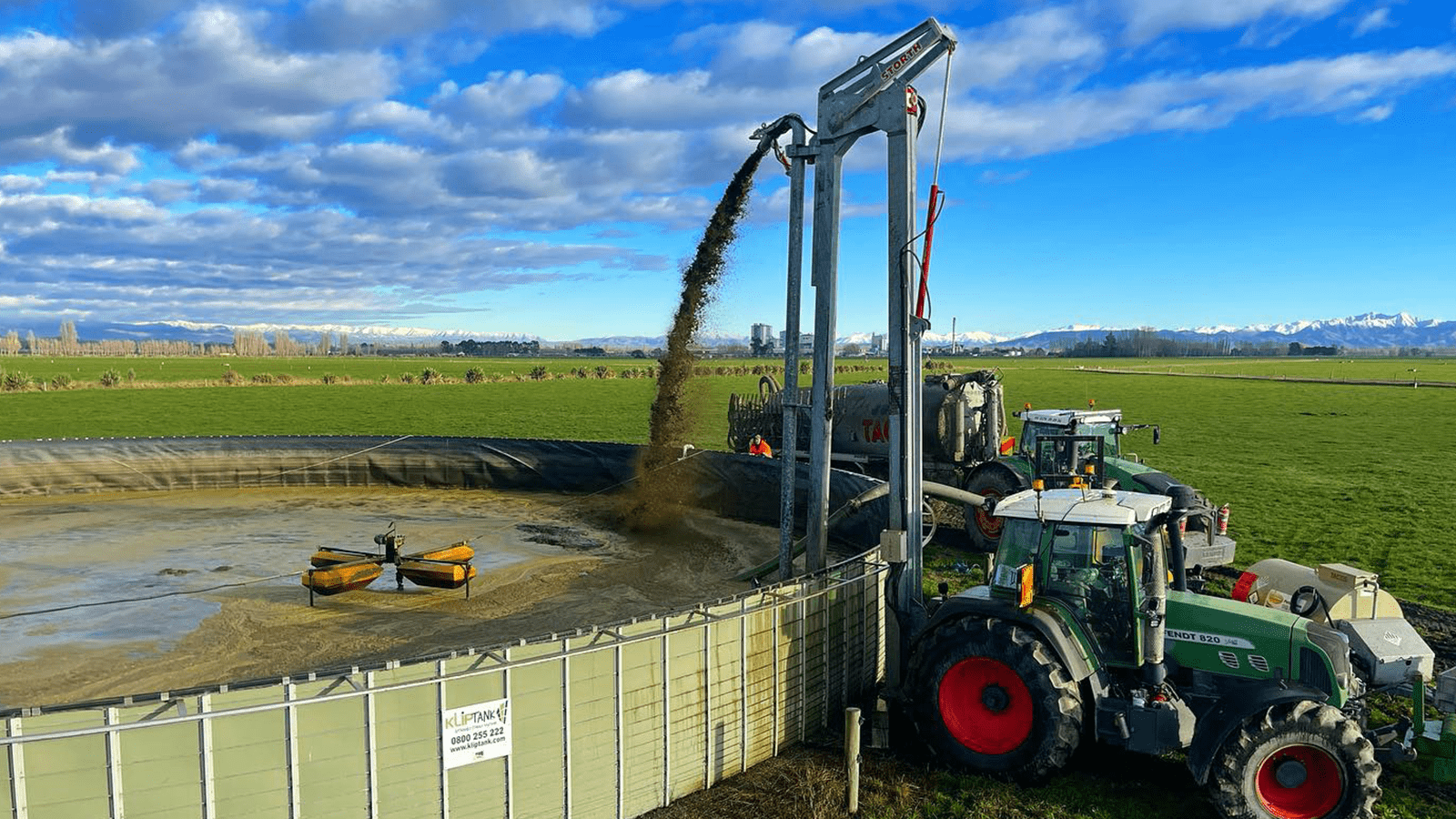

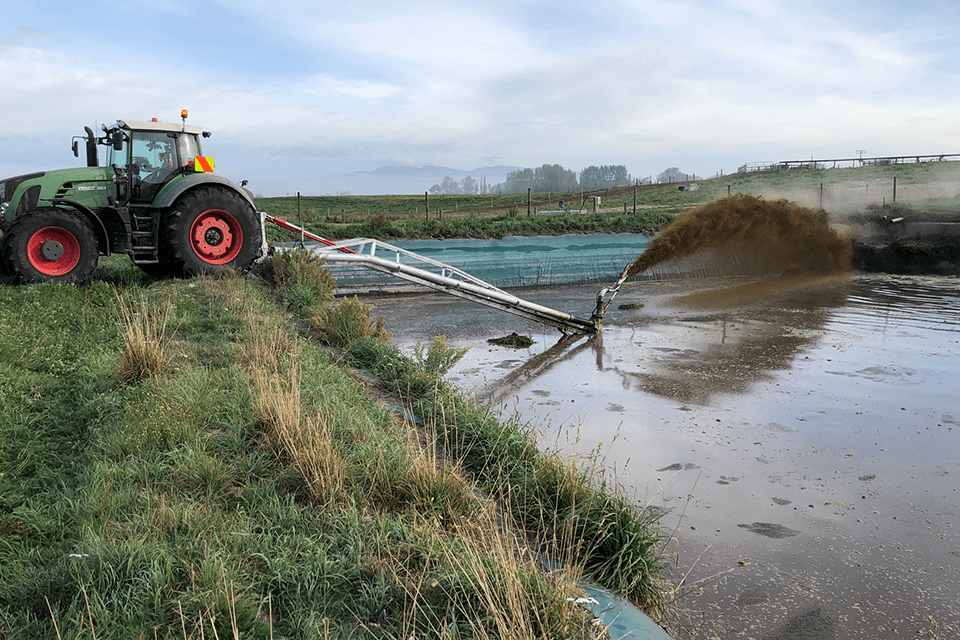

However, maintaining your effluent pond can be a tricky and dirty business. Mixing your pond frequently is vital, and doing it correctly is important to ensure you are maximising the potential nutrition and potential pasture yield.

Here are our top 5 tips on why stirring your effluent pond is a dirty but critical necessity.

|

1) Even, nutrient-rich application – Mixing solids with the liquid means your nutrients are evenly distributed throughout the slurry while creating a smooth consistency for application. FarmChief’s effluent and slurry solutions deliver even, mixed slurry, which is easier to apply with greater nutritional certainty, meaning you know the exact nutritional makeup of the material which is going on the paddock- resulting in better pasture growth and yield.

2) Improved pond & tank capacity – We all know a crusted pond full of solids and sludge reduces has less capacity than ponds with evenly mixed material. Using FarmChief stirrers, mixers and pumps help ensure your pond or tank can operate at 100%, saving you money and time.

3) Reduced long-term work and stress – A well-mixed pond does more than improving the quality of the material: you’ll also notice a large improvement in the smell and look of the pond, keeping you on-side with your neighbours and the council. Mixed slurry is also kinder on pumps and stirrers, meaning fewer blockages & breakages and improved longevity of your implements. Additionally, if your pond or tank is stirred frequently, you’ll spend less time doing this dirty job in the long run – something everyone at home will be happy about! |

|

|

|

4) Improved stock rotation – The more liquid the slurry is when applied to the pasture, the more effectively and quickly the material will be absorbed. This allows you to get stock rotated back onto the land sooner, making land and stock management much less complicated. A liquid slurry is more readily absorbed, meaning you see a quicker uptake of nutrients.

5) Reduced reliance on additional machines – A well-incorporated pond or tank with a smooth slurry consistency means you can spread all the material without worrying about dealing with the solid sludge when emptying the pond. Regardless of your method, umbilical system, tanker, or irrigation, you should be able to do it without getting in a digger and muck spreader to deal with the solids. (FarmChief offers a great range of application methods, talk to us about the one which best suits your needs.) |

Feedback from our customers, both contractors and farmers, indicates that the FarmChief range of mixers, stirrers and pumps are more efficient than others they’ve used and that they can see their ponds moving or breaking up as soon as they start them up.

All FarmChief pond stirrers and pumps are fully galvanised and made with heavy-duty components to ensure a long life span. In addition, less HP is required to stir thanks to their superior design, meaning they are a more accessible machine.

Keen to get started? FarmChief offers a range of mixing, stirring and pumping solutions. Click here for our full range, or give us a call to get a better idea on what solution is right for your setup.

Head over to our website to find the right Stirrer or Pump for your operation.

Contact Us For More Information | Click Here Visit The Product Page

FarmChief

FarmChief