Features and Benefits

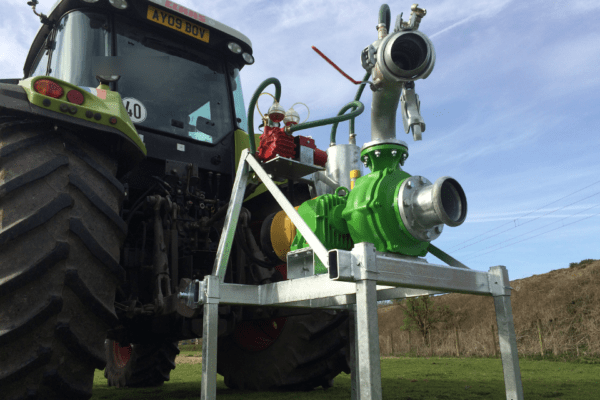

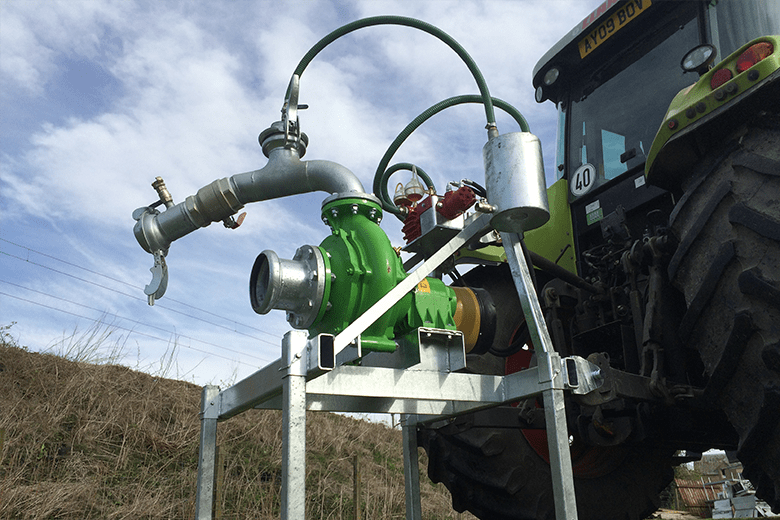

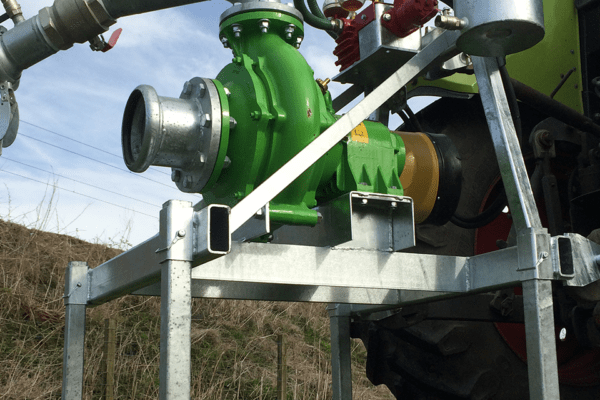

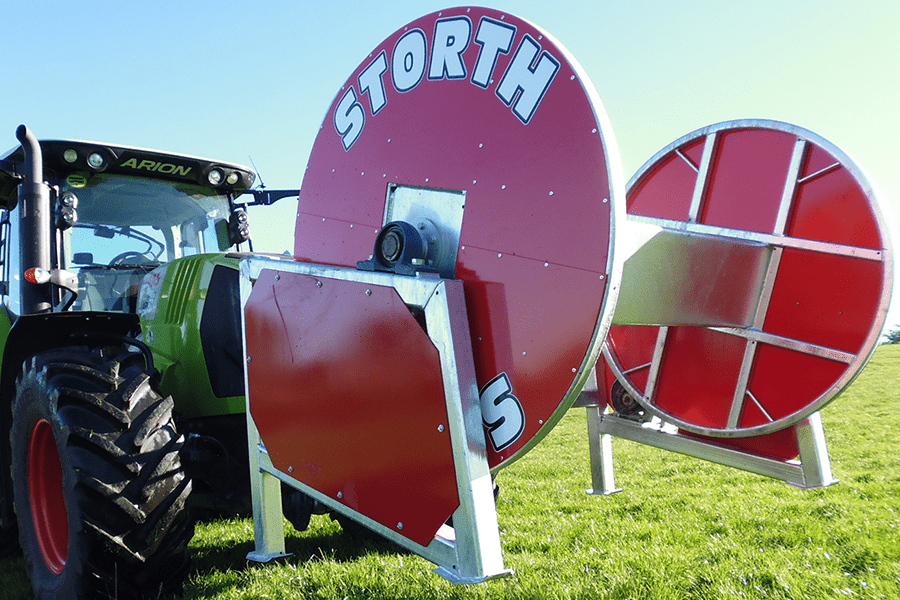

The frame’s design incorporates strength, durability, and ergonomic features to ensure it is the most robust frame on the market.

To draw slurry into the pump, a 4.6m, 200mm intake pipe, is supplied as standard – perfect for pulling slurry from the ponds and priming the pump. Once the slurry is in the pump, the tractor PTO can be engaged and the power transmitted via the shear bolt protected PTO shaft.

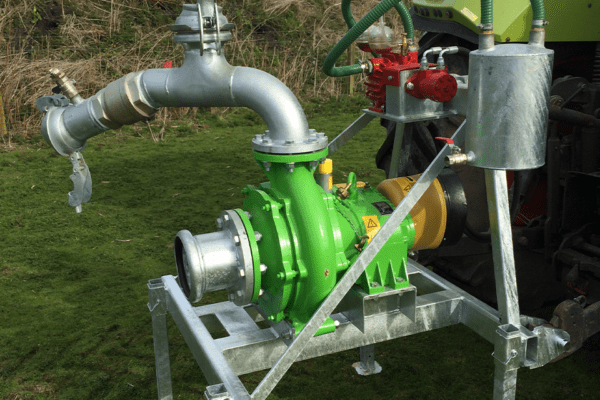

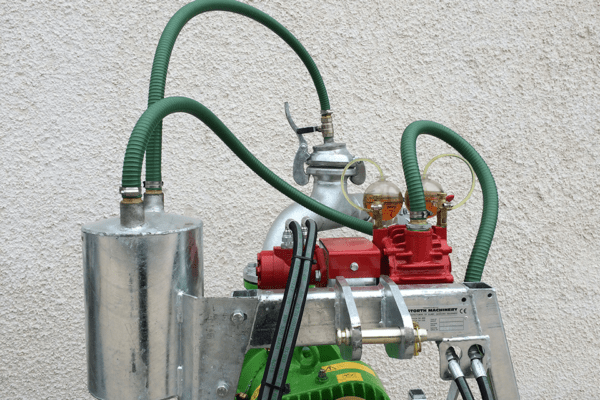

Comfortable and complete control over the pump system is guaranteed thanks to the transparent pipe system, 10L vacuum vessel with a 3/4″ ball valve and heavy-duty vacuum primer providing a continuous vacuum rate of 0.5 bar.

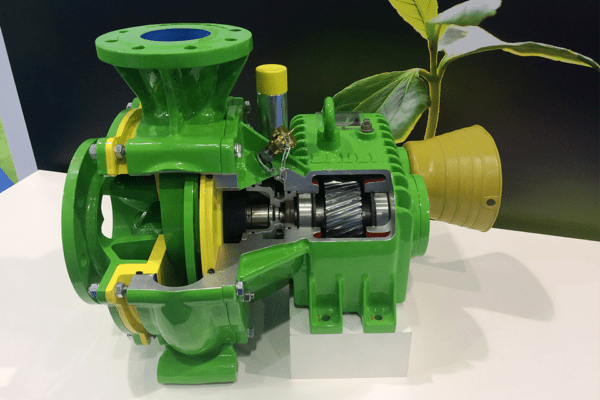

- Mechanical seal run-dry oil protection

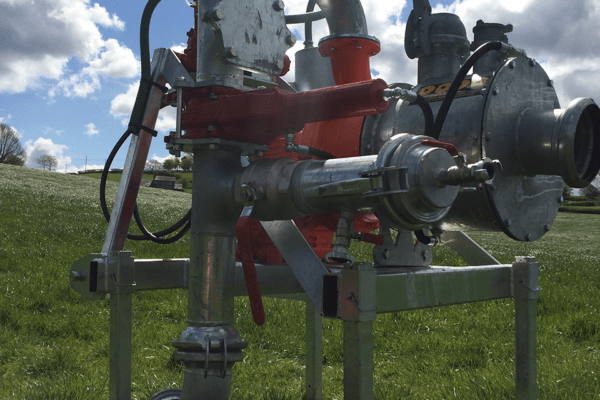

- High-performance wear parts

- Frame versatility and parts

- Standard flexible output pipework solutions

- Operator friendly

FarmChief provides the full spectrum of umbilical parts and accessories for your solution. Find the rest of our range here.