Features and Benefits

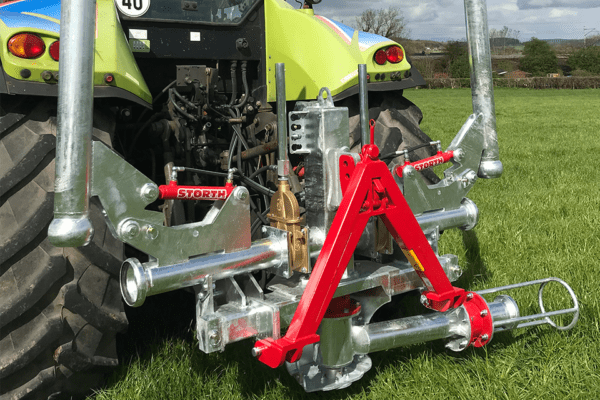

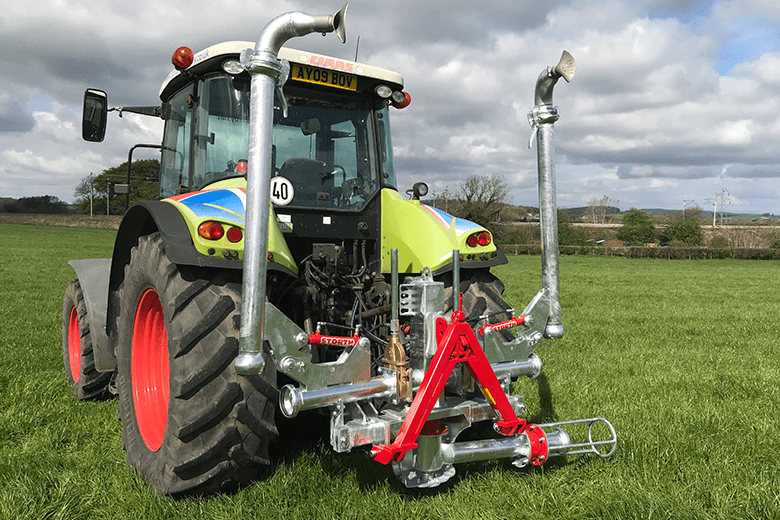

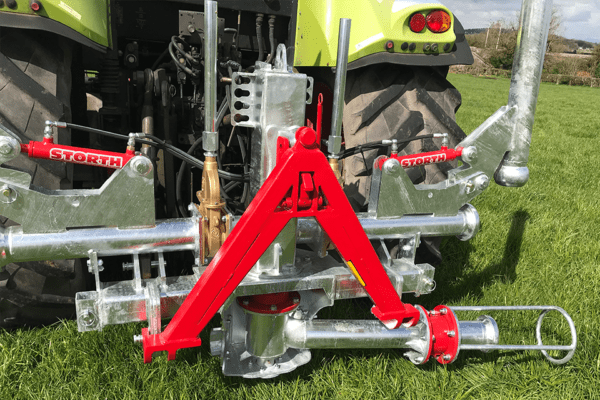

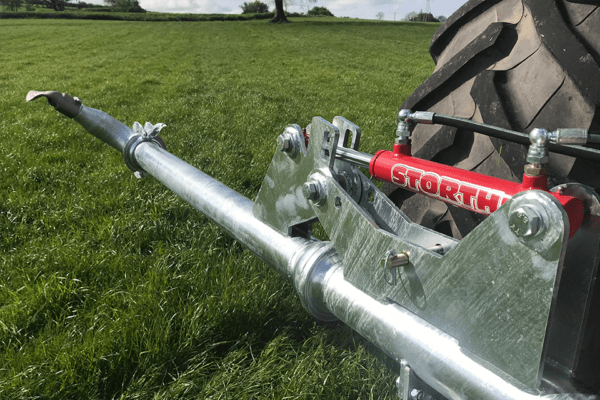

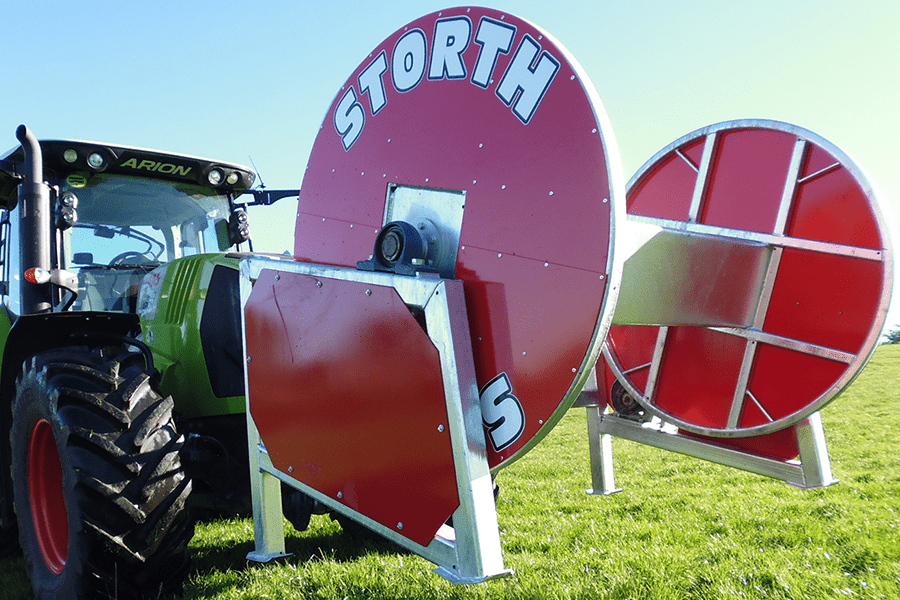

Built from high-quality materials, Storth Spreader Bars are galvanised as standard to help meet the most demanding operating environments. The range offers machines to suit either farmer or contractor, whatever your reeler or spread width preference requirements.

The twin spreader features twin slurry gate valves, enabling independent side shut off for operating close to fences and in tight spots.

Featuring a pivoting 180degree swing arm for ease of movement, or choose an optional 360degree swivel joint for more precise application.

Twin slurry gate valves provide complete operator control, enabling independent side shut-off for operation in tight spots.

- 12m spreading range

- Simple application method

- Efficient work rates

- Low capital investment

- Low running costs & wear

- Minimal working parts means low maintenance

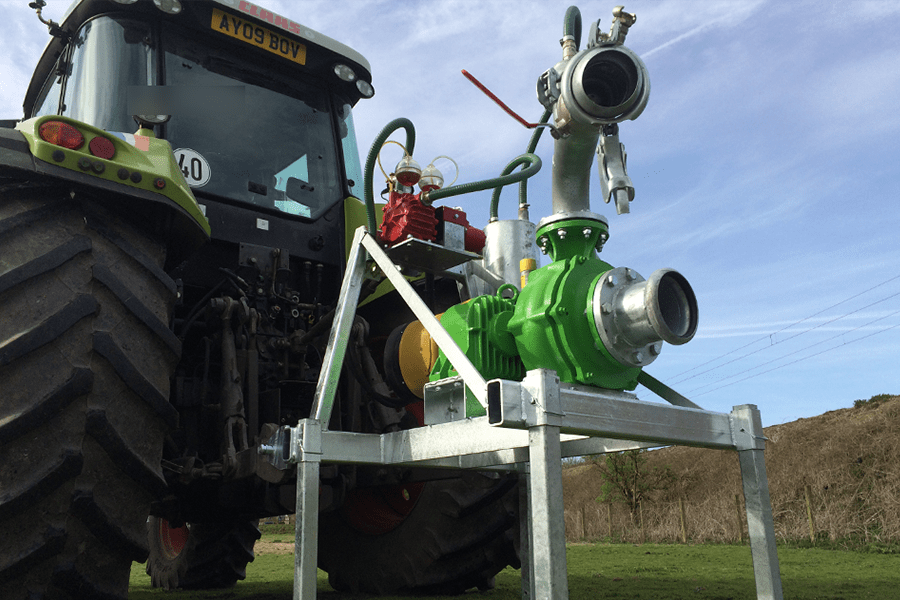

FarmChief provides the full spectrum of umbilical parts and accessories for your solution.