Available now

We have machines ready to be delivered, today. Secure yours today.

Name

Price

Location

FarmChief

FarmChief

Needing something to ensure a precise application of slurry while preventing run-off and nutrient loss? FarmChief Contractor Dribble Bars are the answer.

Our Dribble Bars reduce the surface area of the slurry exposed to the atmosphere, lowering nutrient losses when compared to Spreader Bars.

We have machines ready to be delivered, today. Secure yours today.

Name

Price

Location

Applying effluent via a dribble bar ensures the nutrients go where you want them to go, reduces run off and material loss, while keeping the grass cleaner and reducing smell nusience.

FarmChief Contractor and ContractorPlus Dribble Bars have working widths up to 12m wide and are certainly the strongest dribble bars around. The robust central frame design achieves close coupling, a narrow transport width and great strength to support reeler piggy-backing.

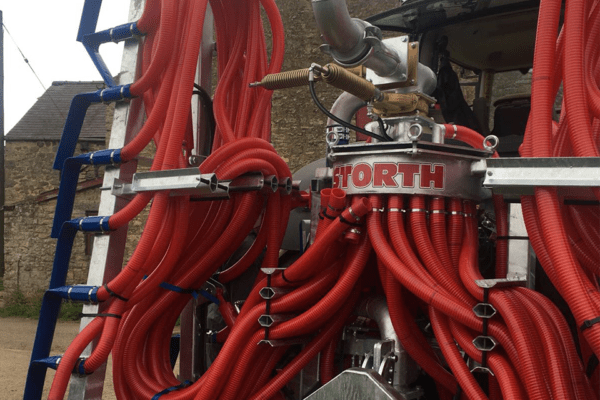

On the Contractor Dribble Bar, the specially designed NovaCut distributor guarantees consistent and accurate material distribution, with uniform application across all of the 40mm distributor outlets, even feeding fibrous slurry. Continuous expansion of the hose joints from distributor to delivery hose eliminates any blockage opportunity.

If you’re looking for more control over the application, choose the top-of-the-range ContractorPlus Dribble Bar. Fitted with a horizontally mounted NovaCut Distributor on each wing of the bar, allowing for hillside feathering, ½ side shut off or complete shut-off. Careful consideration has been given to the build, with it featuring improved rear visibility and ground-level access to the distributors.

Additionally, the extendable 180degree swim arm gives extra support to the incoming pipe, and an optional 4” flow meter can be installed with ease.

FarmChief provides the full spectrum of umbilical parts and accessories for your solution. Find the rest of our range here.

Model

Outlets

Working Width

Weight

Transport Width

Transport Height

Contractor 7531

30

7m

805kg

2.6m

3m

Contractor 9037

36

9m

885kg

2.6m

3m

Contractor 1241

40

12m

960kg

2.6m

3m

Model

Outlets

Working Width

Weight

Transport Width

Transport Height

ContractorPlus 9036

38

9m

935kg

2.75m

3m

ContractorPlus 1240

40

12m

1085kg

2.75m

3m