Introducing Överum Ploughs – Quality, Strength and Precision.

We are excited to announce that FarmChief Machinery is now the exclusive dealer for the world-renowned Överum range of ploughs in New Zealand.

Innovation and new ideas are truly the name of the game at the moment, with bright thinking bringing efficiencies and cost savings to New Zealand farms. However, with around 50 years of experience under our belts, we also know that sometimes new technologies just don’t stack up against the tried and true – this is why we’re bringing back the plough!

Needing little introduction, the Överum range has been forged from over 170 years of agricultural manufacturing, specialising in modern steelwork to achieve outstanding results in both durability and strength. Coupled with excellent lifetime performance, significant product developments have resulted in Överum ploughs requiring very low energy consumption when compared to others on the market.

With a large range and multiple variations per product (including headstock, plough boards, coulter numbers and type of stone release system), the Överum range from FarmChief can produce an excellent result in all types of soil and environmental conditions. Discover the quality of Överum ploughs from FarmChief. Designed to guarantee high-quality ploughing, easy set-up and a favourable economy, Överum ploughs are in a class of their own. Their durable frames, manufactured using only the best quality raw materials ensure a long life and maximum output.

Benefits of ploughing.Of all the tools used for mechanical weed control, it is the plough that has made itself known as the most reliable over the centuries. The threat of herbicide-resistant weeds is increasing and is forcing many of today’s farmers to act and again use ploughing as their key strategy for weed control. The plough has many advantages:

Considering the modern cultivation challenges farmers across New Zealand are facing (high-use paddocks making it difficult to maintain and promote a healthy soil structure), the ploughing action can have a significantly positive impact on soil health and productivity. Thanks to the loosening up of the topsoil, damage caused by field traffic can be repaired, aeration of compacted soil can be achieved, water stores can be accessed, and nutrients can be mineralised and benefit new crops. As well as eliminating weed growth, the stubble and trash that snails and insects thrive on are effectively removed from the soil, decreasing the need for costly spray programs. |

|

|

What does the research say?The Swedish University of Agricultural Sciences in Uppsala has studied how much energy is needed to loosen up top soil using different implements. Plough, tooth cultivator and disc implements were compared. Results indicated that a plough is an efficient tool for loosening up soil, combating weeds and incorporating plant reside and manure. Specifically:

|

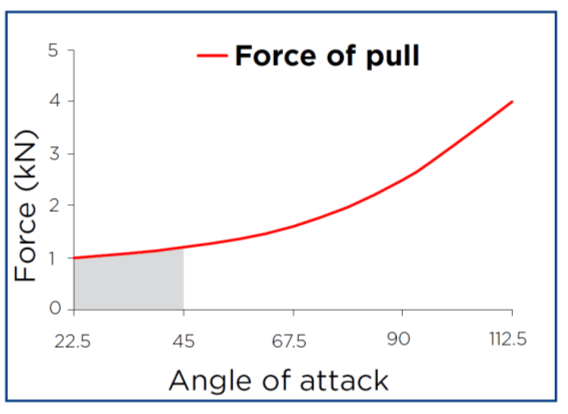

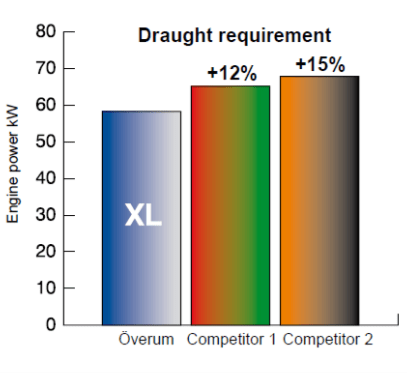

The correct angle is essential.Importantly, after using a plough body specifically designed and manufactured by Överum, the bottom of the furrow is not smooth or packed like it is from many other brands. The rake angle of the share to the soil is directly related to the resulting cultivation work. Additionally, the rake angle also has a significant bearing on the draught requirement, or the power used to operate the plough. Överums sharp wearing parts combined with a favourable rake angle deliver a low draught requirement and a cheaper implement to run. The JTI research institute has made a comparison of the draught requirements of the three most common plough brands. A 100 hp measuring tractor was used to pull the four-furrow reversible ploughs. The furrow width was adjusted to 40 cm and the ploughing depth was 20 cm. The diagram shows that the Överum plough with XL bodies was the one with the lowest draught requirements. This result means less slippage and higher efficiency, giving lower fuel consumption and cultivation costs. Crucially, the Överum XL body has the lowest draught requirement on the market. |

|

Click here to explore the FarmChief Överum range today.

FarmChief Machinery has been New Zealand’s cultivation solution specialists for around 50 years. During that time we’ve continued to provide speciality products, services and advice. We’re excited to add these impressive ploughs to our range to further extend our world-class solutions.

For a free demonstration, consultation or quote, contact our experts | Click here to explore our full range of cultivation solutions.

FarmChief

FarmChief