Features and Benefits

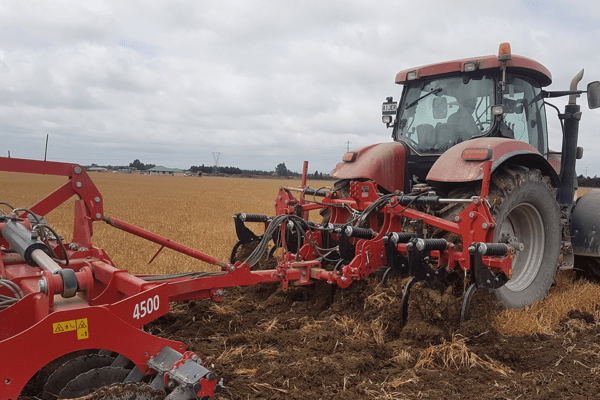

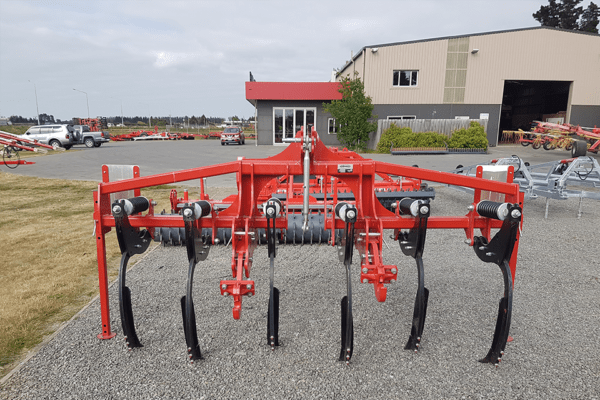

The ExpressPro Pre-Ripper features a unique twisted shin which is great for burying trash and minimising passes. Rear or front mounting options make it a versatile option for most farmers.

- The rear 2ptl set-up allows towing of Speed Discs as an ideal combination

- Sprung auto-reset legs

- 600mm working depth

- 500mm leg spacing

- Rear or front mounting options

- Optional winged feet, straight leg and depth wheels

- 3m, 4m & 6m working widths